Interfacing ANSYS and LS-DYNA

Sample Problem #4: Rigid Cylindrical Bar Moving Along the Z-Axis and

Impacting a Plate in the X-Y Plane that is Supported by Other Plates Normal to

It

Pre-Processing

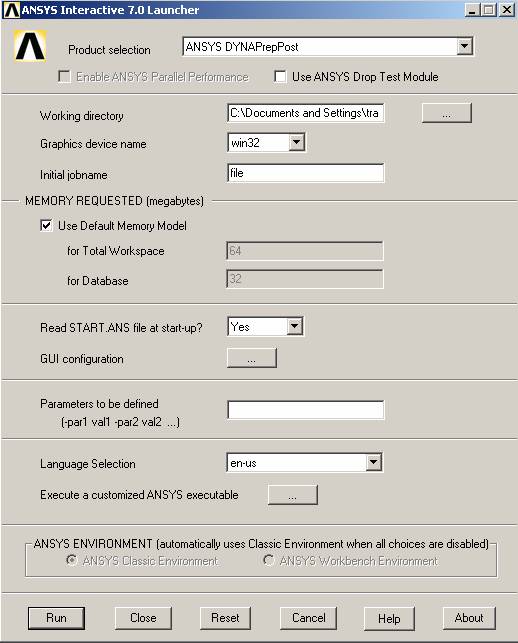

Open ANSYS

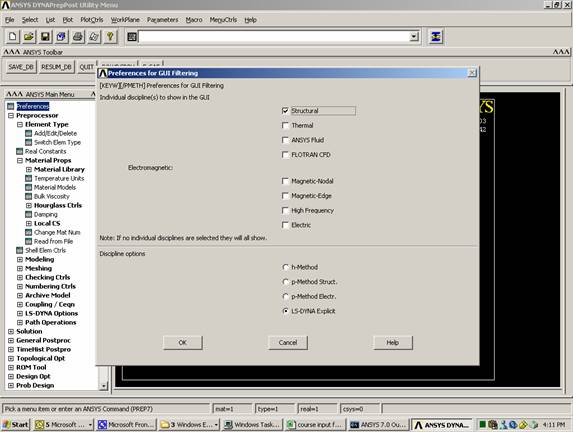

∑ ANSYS Interface has pull-down menu on the top. These menus cover functions such as plotting, display, and selection of entities. Help menu is also at this location.

∑ ASNSY has also menus on the left side of the screen. These menus cover pre-processing, processing, and post-processing.

∑ ANSYS needs to know that you are planning to create LS-DYNA model. That is why you need to select LS-DYNA Explicit in the Preferences

In Windows, select Start

Programs

ANSYS Release 7.0

ANSYS Interactive

††††††††††† In Product Selection, choose: ANSYS DYNAPrepPost

††††††††††††††††††††††† Run

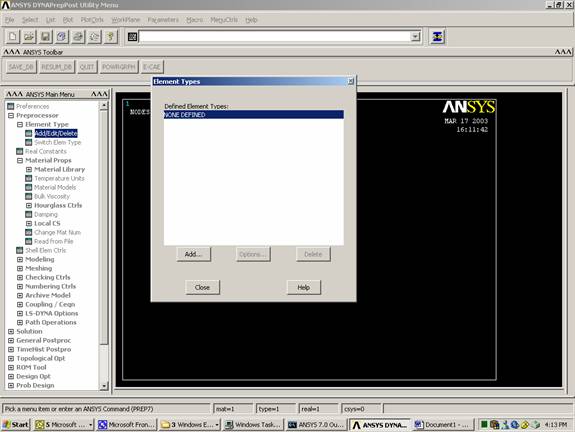

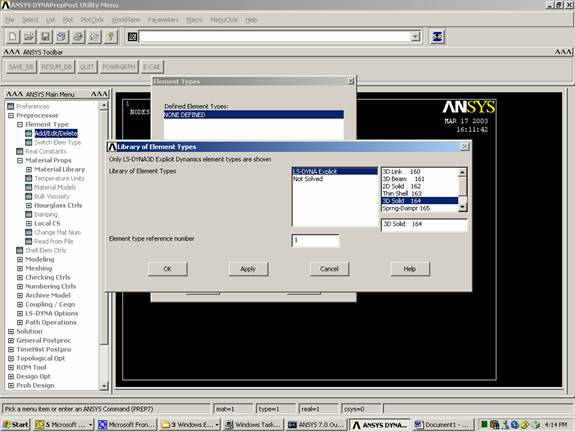

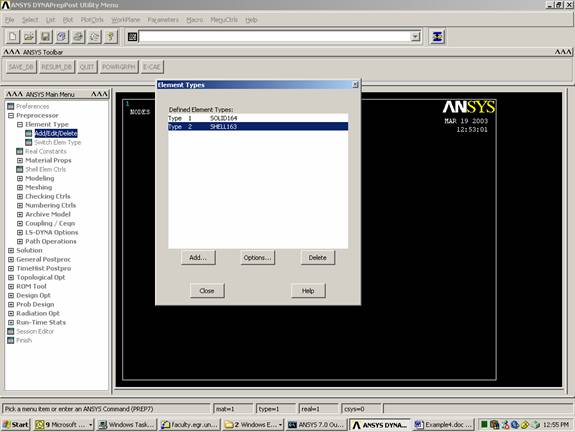

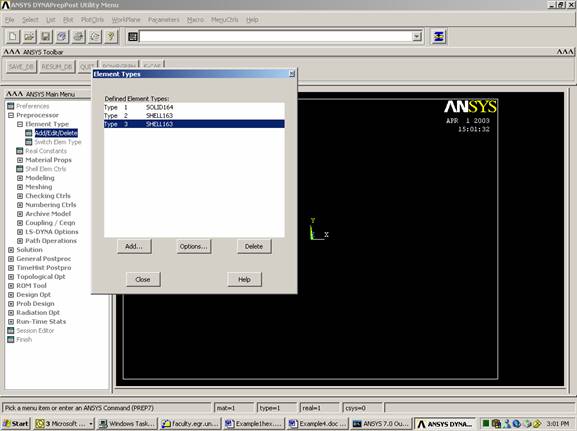

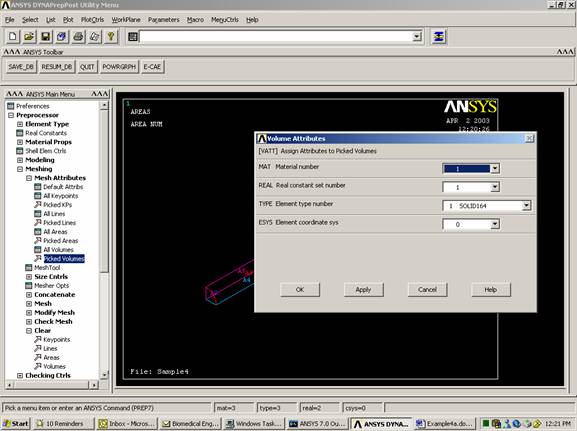

Define element type

Element Group #1: solid element,

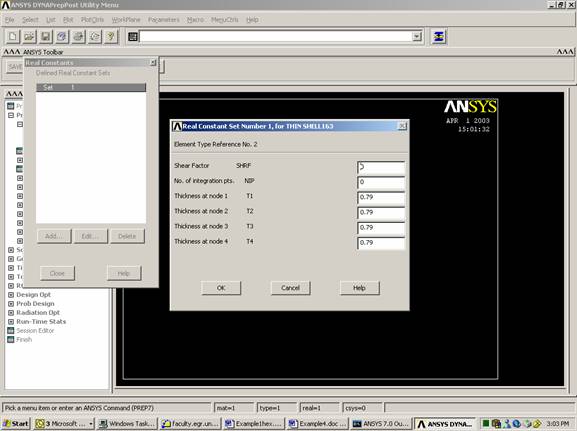

Element Group #2: shell element (thickness=0.79),

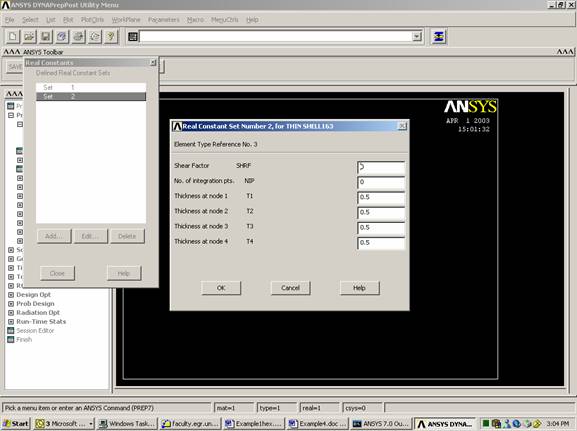

Element Group #3: shell element (thickness=0.5)

†

†

Assign Thickness to

the Plates

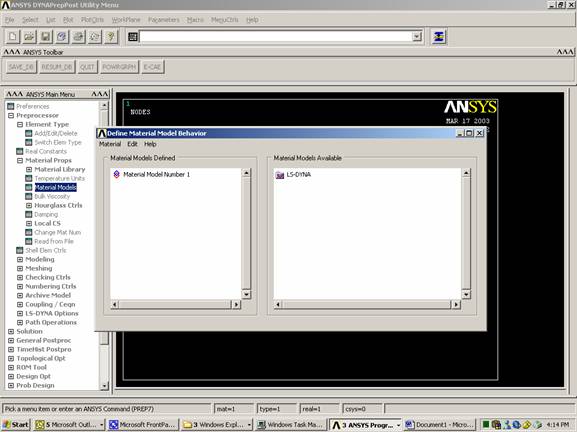

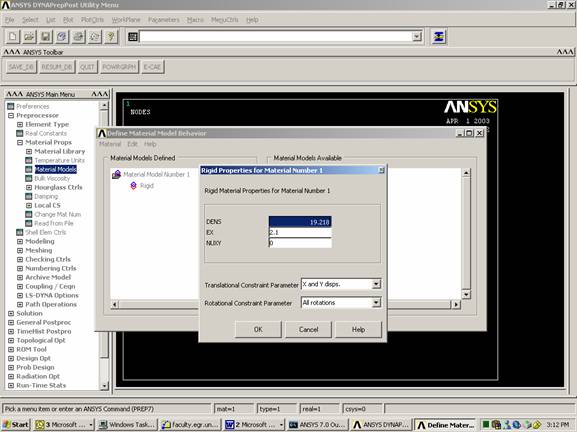

Define material type.

Rigid material is used for group #1 with the following characteristics:

Density (g/cm3) = 19.218

Elastic Modulus (g/msec2 cm) = 2.1

Poissonís Ratio = 0.0

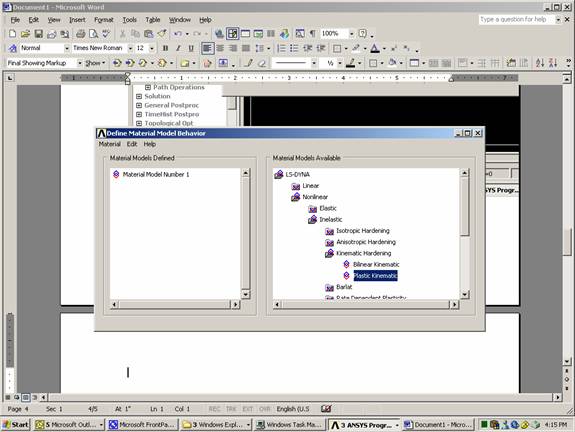

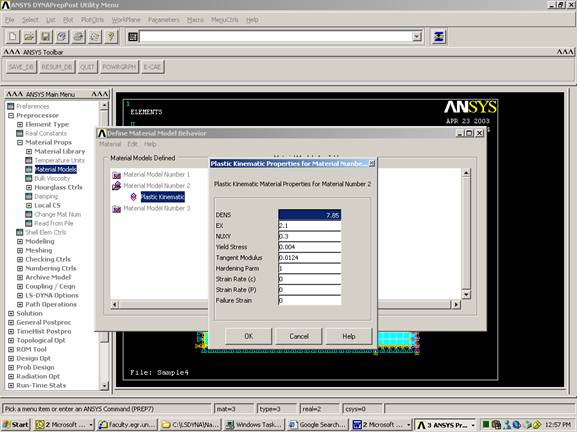

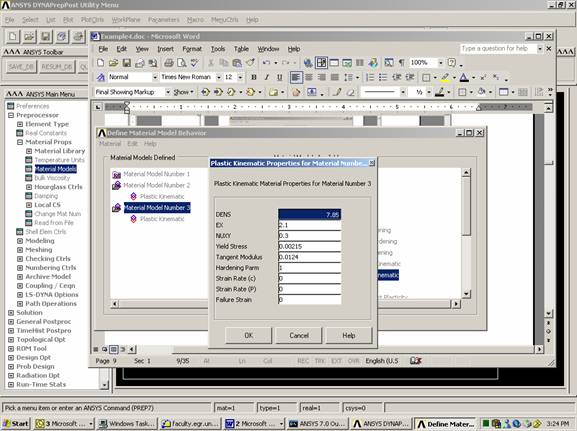

Inelastic, plastic kinematic material is used for group #2 with the following characteristics:

Density (g/cm3) = 7.85

Elastic Modulus (g/msec2 cm) = 2.1

Tangent Modulus (g/msec2 cm) = 1.24x10-2

Yield Strength (g/msec2 cm) = 4.0x10-3

Poissonís Ratio = 0.3

Hardening Parameter = 1.0

Inelastic, plastic kinematic material is used for group #3 with the following characteristics:

Density (g/cm3) = 7.85

Elastic Modulus (g/msec2 cm) = 2.1

Tangent Modulus (g/msec2 cm) = 1.24x10-2

Yield Strength (g/msec2 cm) = 2.15x10-3

Poissonís Ratio = 0.3

Hardening Parameter = 1.0

†

†

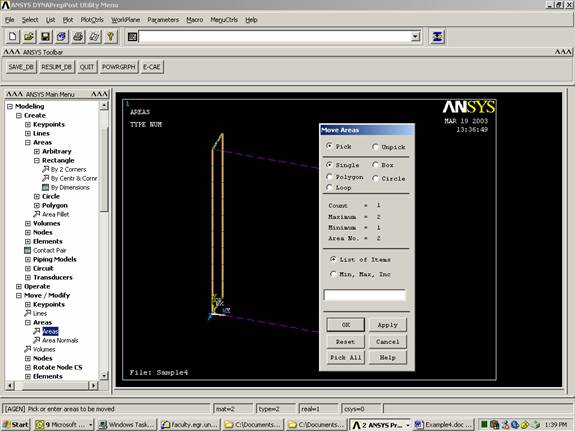

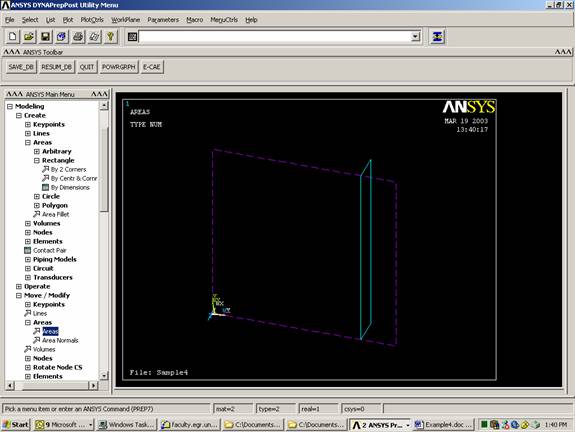

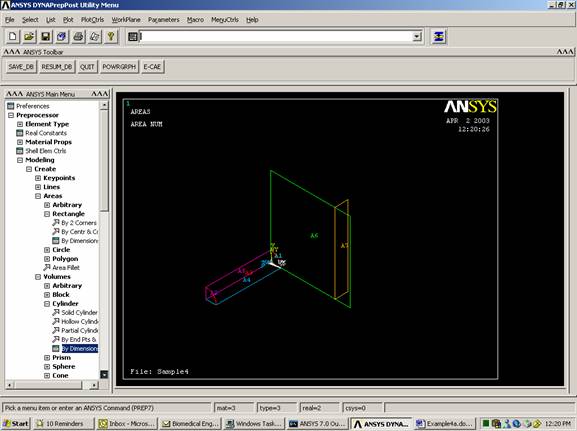

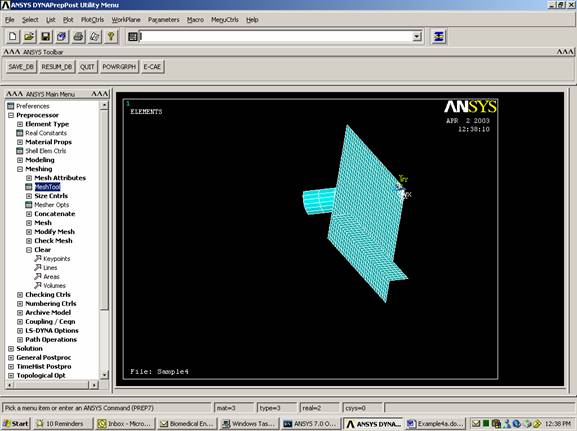

Create the plates

WorkPlane

††††††††††† Offset Work Plane by Increment

††††††††††††††††††††††† Rotate +Y (90 degrees)

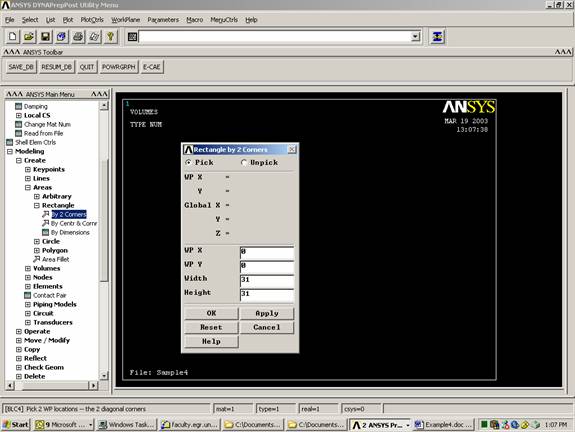

Create rectangle (0,0,5,31)

shift by 25,0,0

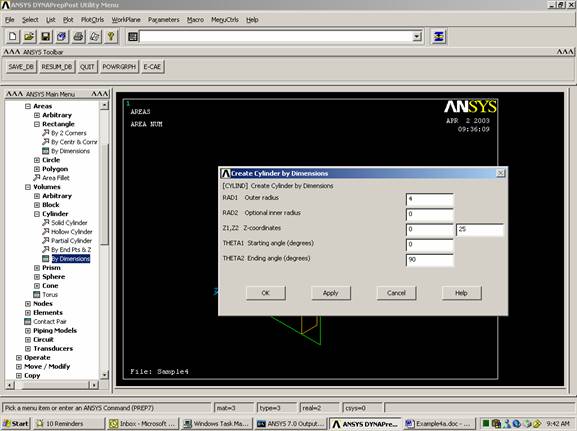

Create Volume

WorkPlane

††††††††††† Offset Work Plane by Increment

††††††††††††††††††††††† Rotate -Y (90 degrees)

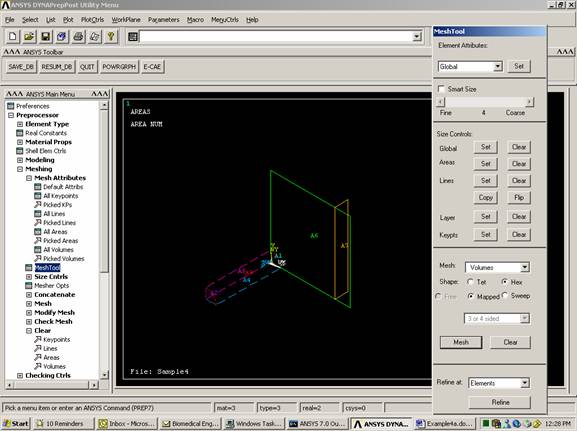

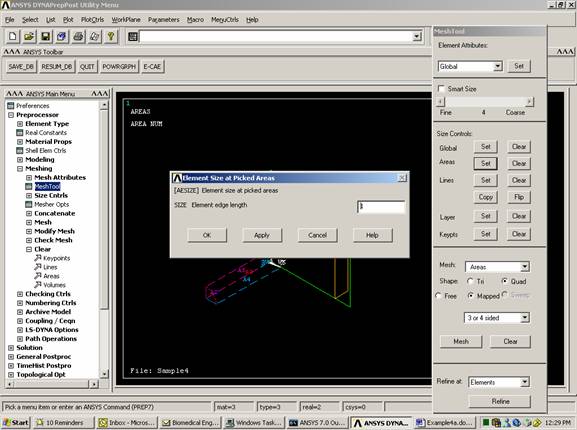

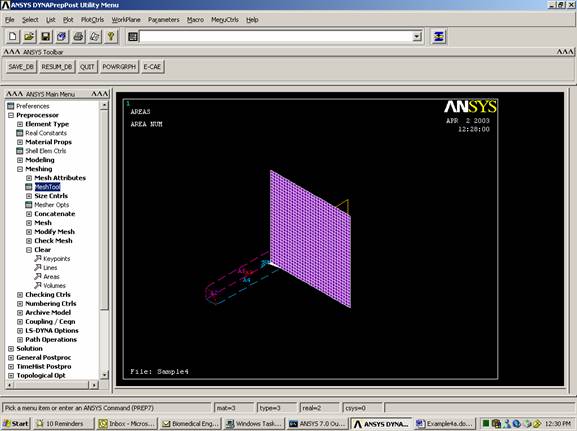

Note: Turn off smart size if it is on.

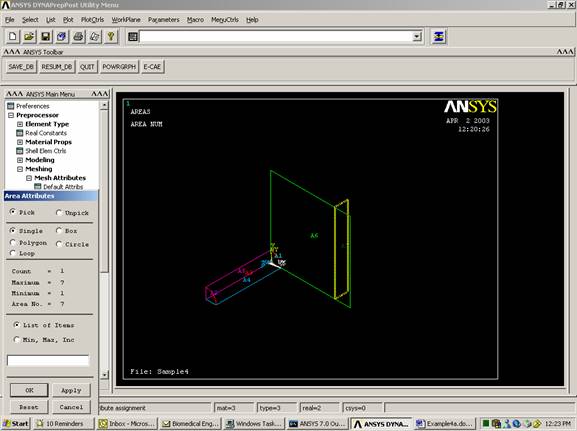

Plot

††††††††††† Areas

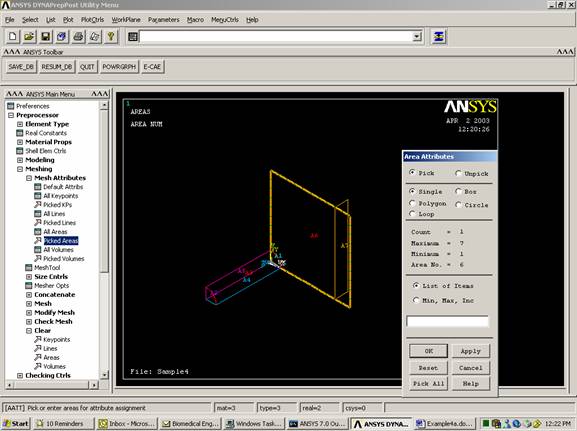

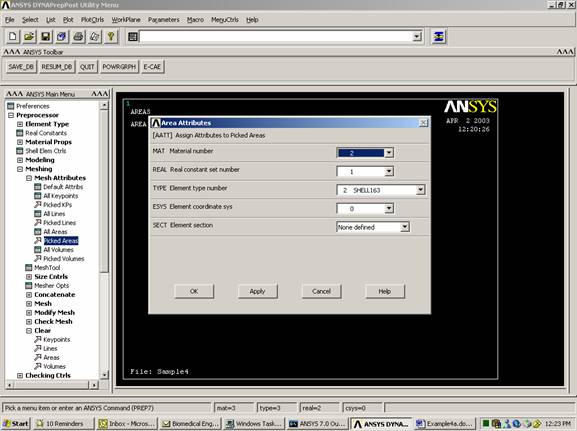

Select Mesh Tool

Set Areas

Select the big square

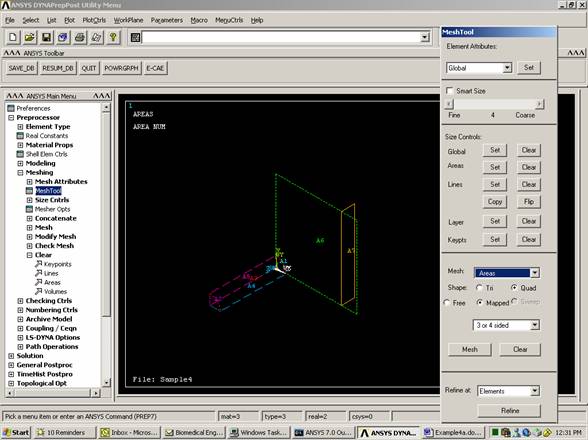

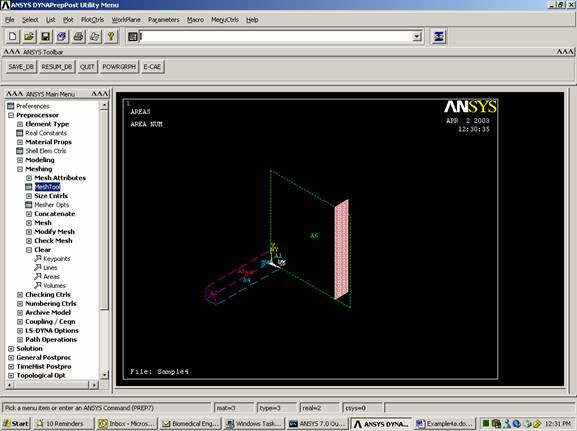

Plot

††††††††††† Areas

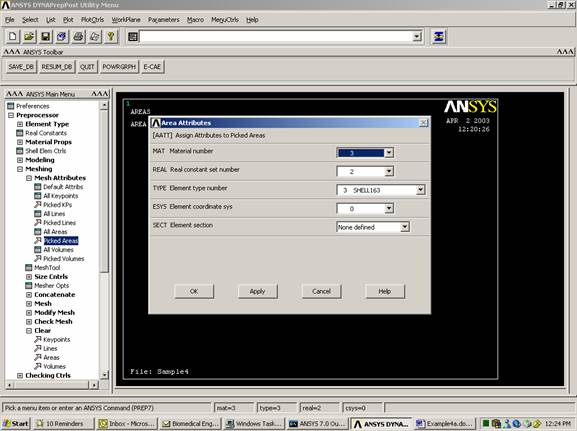

Select Mesh Tool

Set Areas

Select the small rectangle

Plot

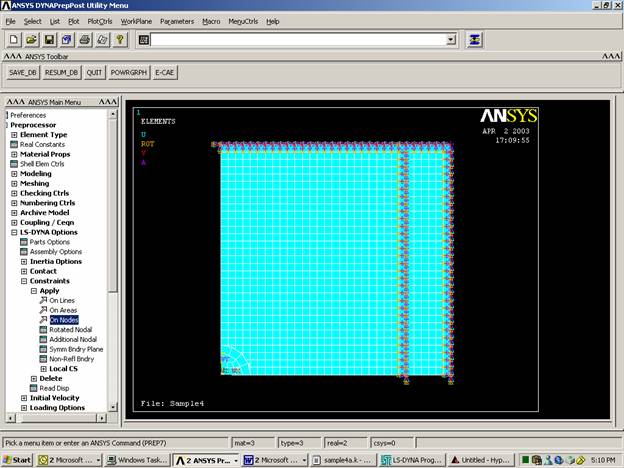

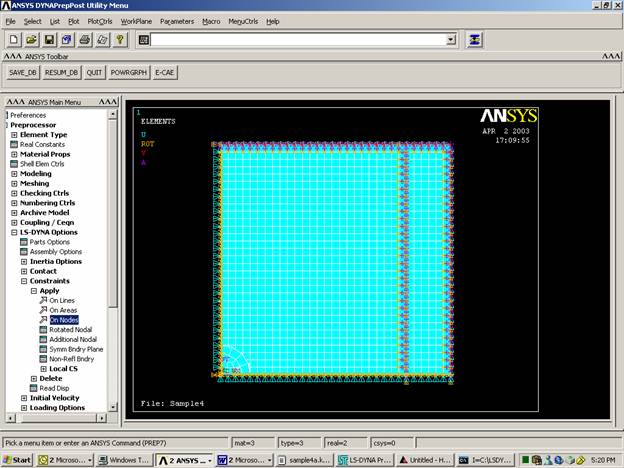

††††††††††† Elements

PlotCtrls

††††††††††† Pan, Zoom, Rotate

††††††††††† Click on Dynamic Mode

††††††††††††††††††††††† Use right mouse button

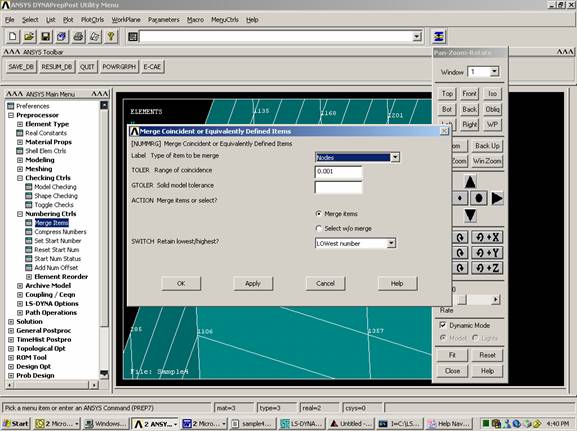

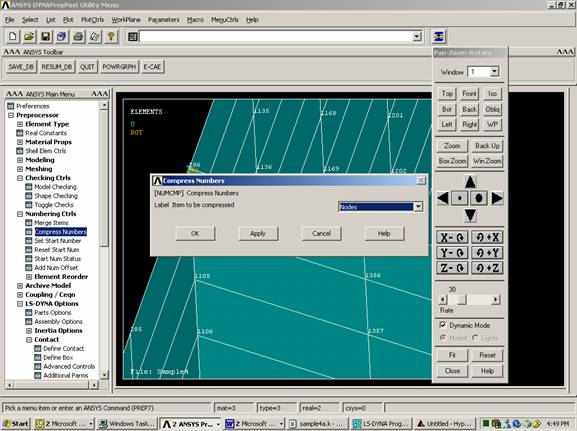

Merge nodes

Some of the nodes are in the same location. They should be merged.

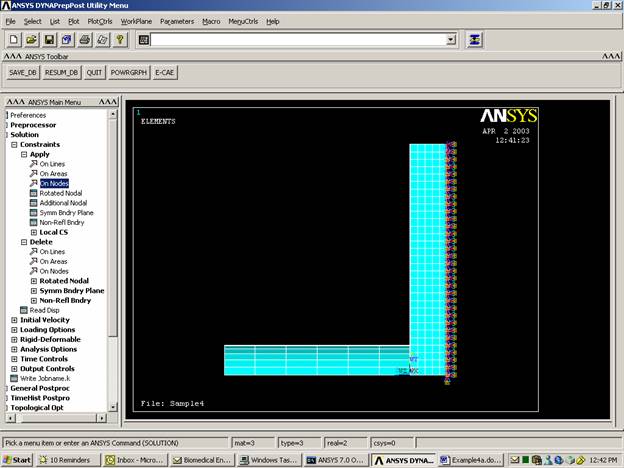

Boundary conditions

PlotCtrls

††††††††††† Pan, Zoom, Rotate

Click on right

Choose the nodes on the bottom of the smaller plate. Restrict them completely

Click on front

††††††††††† Choose the nodes on the left edge of the plates. Restrict them UX, RY, RZ.

††††††††††† Choose the nodes on the lower edge of the plate. Restrict them in the UY, RX, RZ

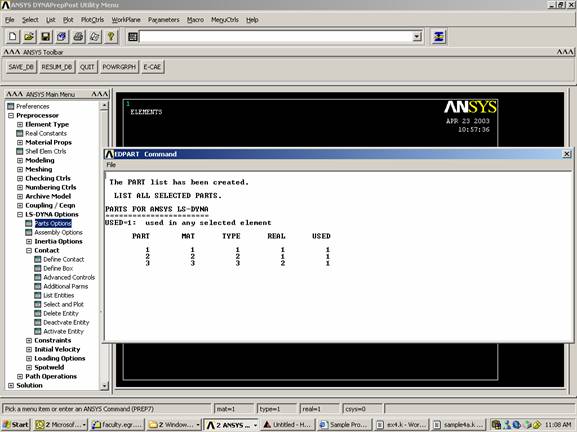

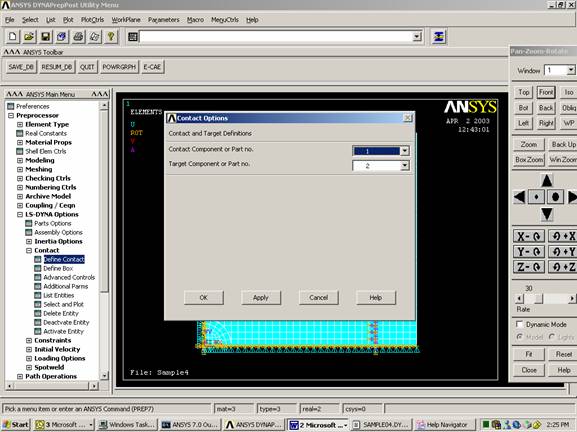

Contact

Make contact between a 4x4 square on the horizontal plate

and the lower surface of the cylinder.

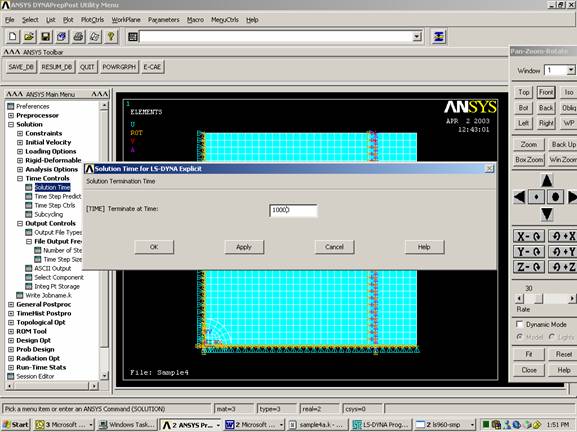

Set Time Controls

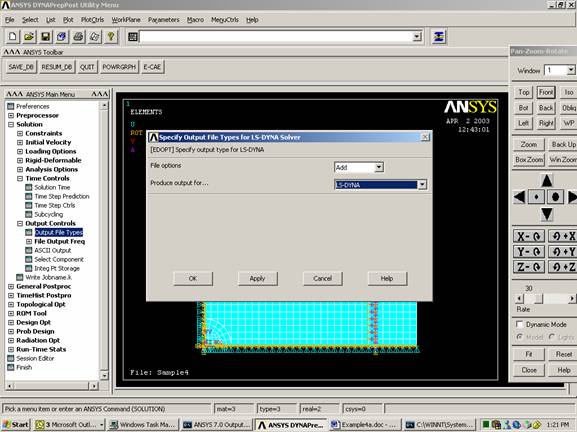

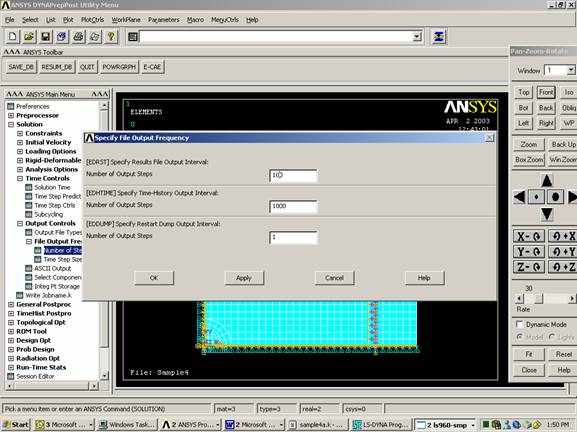

Set Output Controls

(You can specify the output to either ANSYS, LS-DYNA, or both)

Specify the Output

Frequency

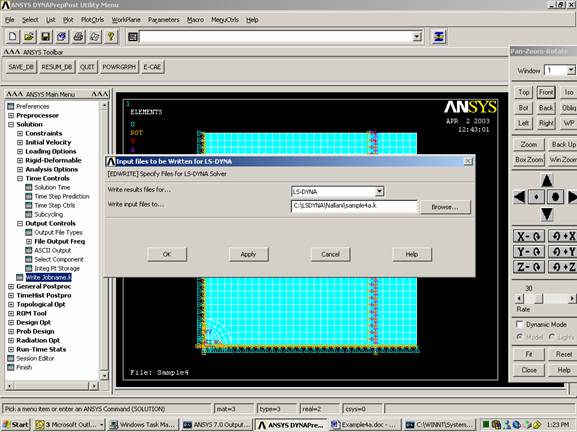

Save File (It is very important to save in ANSYS format (*.db) since it cannot read DYNA format (*.k))

File

††††††††††† Save As

††††††††††††††††††††††† Sample4a.db

Initial Velocity:†††††††††

Initial velocity and contact can be input in ANSYS by creating component and assigning the initial velocity or contact specification to this component. It is much easier to create boxes that enclose the nodes within specific segments of your model.† You can do this by adding the following to your *.k program. In this section two boxes are created:

∑

∑

Place the text near the end of the *.k file.

$

$†††† define section

$

*DEFINE_BOX

$††††††† i†††††††† f†††††††† f†††††††† f†††††††† f†††††††† f†††††††† f

$††† boxid†††††† xmm††††††

xmx†††††† ymn†††††† ymx††††††

zmn†††††† zmx

†††††††† 1-7.302E-07†† 31.0000-7.302E-07†† 31.0000††††††

0.0†† 5.00000

*DEFINE_BOX

$††††††† i†††††††† f†††††††† f†††††††† f†††††††† f†††††††† f†††††††† f

$††† boxid†††††† xmm††††††

xmx†††††† ymn†††††† ymx††††††

zmn†††††† zmx

†††††††† 2-1.565E-07†† 4.00000-1.565E-07†† 4.00000††

5.00500†† 30.0000

$

$†††† initial condition

section

$

*INITIAL_VELOCITY

$††††††† i†††††††† i†††††††† i

$†††† nsid††† nsidex††††

boxid

†††††††† 0†††††††† 0†††††††† 1

$††††††† f†††††††† f†††††††† f†††††††† f†††††††† f†††††††† f

$†††††† vx††††††† vy††††

†††vz††††††† wx††††††† wy††††††† wz

†††††† 0.0††††††

0.0†††††† 0.0†††††† 0.0††††††

0.0†††††† 0.0

*INITIAL_VELOCITY

$††††††† i†††††††† i†††††††† i

$†††† nsid††† nsidex††††

boxid

†††††††† 0†††††††† 0†††††††† 2

$††††††† f†††††††† f†††††††† f†††††††† f††††††† †f††††††††

f

$†††††† vx††††††† vy††††††† vz††††††† wx††††††† wy††††††† wz

†††††† 0.0††††††

0.0-1.800e-03†††††† 0.0†††††† 0.0††††††

0.0

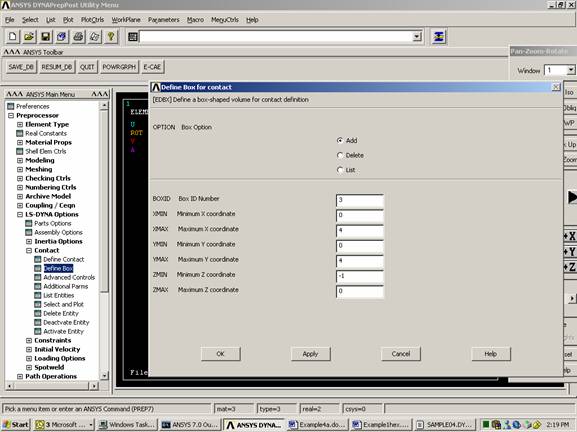

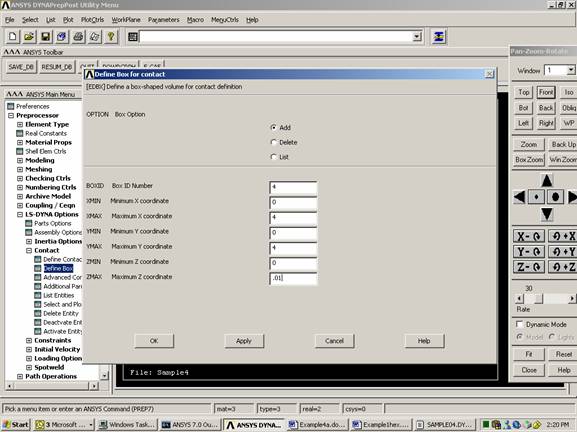

Contact

Another method to

define contact

Define contact between the lower surface of the cylinder and a 4x4 square patch of the horizontal plate. Place the text near the end of the *.k file.

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$††††††††††††††††††††††††††††† CONTACT

DEFINITIONS†††††††††††††††††††††††††††† $

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$

*DEFINE_BOX

$††††††† i†††††††† f†††††††† f†††††††† f†††††††† f†††††††† f†††††††† f

$††† boxid†††††† xmm††††††

xmx†††††† ymn†††††† ymx††††††

zmn†††††† zmx

†††††††† 3,0.00,4.0,0.0,4.0,0.00,0.01

$

*DEFINE_BOX

$††††††† i†††††††† f†††††††† f†††††††† f†††††††† f†††††††† f†††††††† f

$††† boxid†††††† xmm††††††

xmx†††††† ymn†††††† ymx††††††

zmn†††††† zmx

†††††††† 4,0.00,4.0,0.0,4.0,-1.00,0.0

$

*CONTACT_TIED_SURFACE_TO_SURFACE

†††††††† 0†††††††† 0†††††††† 0†††††††† 0†††††††† 3†††††††† 4††††††† 0†††††††† 0

†0.000††††

0.000†††† 0.000†††† 0.000††††

0.000†††††††††††† 0 0.000††† 0.1000E+08

†1.000††††

1.000†††† 0.000†††† 0.000††††

1.000†††† 1.000†††† 1.000††††

1.000